Our Products

Product overview

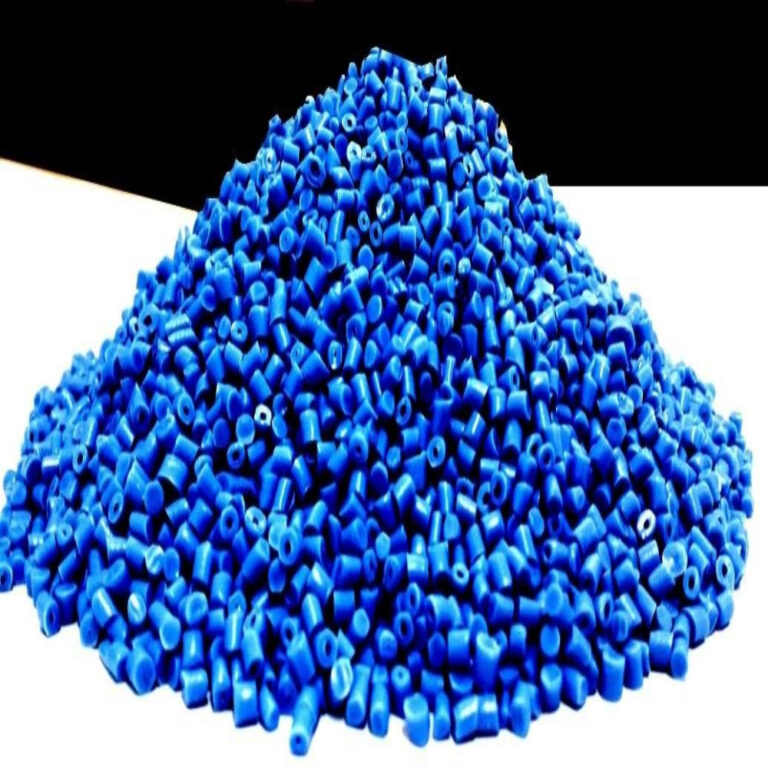

A. Polypropylene (PP)

B. PET Resin

our premium PET (polyethylene terephthalate) resin that sets the standard for packaging excellence.

Homopolymer

Bottle Grade

Random Copolymer

Film Grade

Impact Copolyme

Textile Grade

VIRGIN POLYMER

We deliver high quality polymer from Dubai & United Arab Emirates, Asia for demanding company

The PET bottles used for regrinding are typically transparent or light blue in color. They could be sourced from various consumer products such as water bottles, soda bottles, or other PET packaging containers. These bottles undergo a recycling process to convert them into regrind material, which can be used as a raw material in the production of new plastic products.

This high-quality raw material can be utilized across various industries, ensuring a circular economy while reducing the environmental impact of plastic waste.

- Source: Water bottle (5 gallons)

- Colors: Transparent light blue

- Packing (Shipping bags): Jumbo bags

PET Preform Regrind

The clear and light blue mix indicates that the regrind contains a blend of clear (transparent) PET bottles.

PET bottles

PET bottles with a light blue tint. The mix of colors may vary depending on the specific recycling stream.

Recycled Material

This recycled material can be utilized in various industries, including packaging, textiles, fibers, automotive, and construction, among others

HDPE Film / Injection & Blow Material (Solid & Regrind)

HDPE Film / Injection & Blow Material (Solid & Regrind) refers to a specific type of recycled plastic material derived from High-Density Polyethylene (HDPE). This material can be sourced from various post-consumer or post-industrial sources, such as packaging films, injection-molded products, and blow-molded containers.

HDPE Film refers to thin plastic sheets or films made from HDPE, commonly used in applications like plastic bags, shrink wraps, and packaging films. Injection & Blow Material refers to HDPE in the form of solid parts, such as plastic containers, bottles, or other rigid plastic products.

- Source: Water bottle (5 gallons)

- Colors: Transparent light blue

- Packing (Shipping bags): Jumbo bags

Advantages & applications

As for the advantages of HDPE film in a professional context, here are some general advantages of HDPE film:

Durability: HDPE film is known for its high strength and durability. It can withstand various environmental conditions and resist tearing, puncturing, or other damages.

HDPE Film refers to thin plastic sheets or films made from HDPE, commonly used in applications like plastic bags, shrink wraps, and packaging films. Injection & Blow Material refers to HDPE in the form of solid parts, such as plastic containers, bottles, or other rigid plastic products.

The material can be available in both solid and regrind forms. Solid HDPE denotes the original form of the plastic, while regrind refers to recycled HDPE that has undergone a grinding process to be converted into granules or flakes.

DPE is known for its excellent strength, durability, and chemical resistance, making it suitable for various applications. Recycled HDPE offers environmental advantages by diverting plastic waste from landfills and reducing the demand for virgin plastic production.

The material can be used in a wide range of industries, including packaging, construction, automotive, and agriculture. In the packaging industry, HDPE can be utilized to manufacture new plastic bags, containers, and bottles. In the construction sector, it can be employed for pipes, geomembranes, and other construction materials. HDPE also finds application in creating products like toys, household goods, and various plastic components.

HDPE film is highly resistant to moisture and acts as a good barrier against water vapor. It is commonly used for packaging perishable goods, as well as in applications where moisture protection is required.

HDPE (High-Density Polyethylene)

HDPE (High-Density Polyethylene) film refers to thin plastic sheets made from HDPE material. HDPE is a type of polyethylene plastic that is known for its high density and strength. The film is typically produced in roll or sheet form and is available in various thicknesses and sizes.HDPE film offers several advantages in professional applications:Durability: HDPE film is highly durable and can withstand harsh conditions without easily tearing or puncturing. It is resistant to impact and can provide long-lasting protection.

HDPE film can be easily customized and fabricated to meet specific requirements. It can be heat-sealed, folded, or cut into desired shapes and sizes. This versatility makes it suitable for a wide range of applications, from packaging and agriculture to construction and manufacturing.

Recyclability: HDPE is a highly recyclable material. HDPE film can be recycled and processed into new products, contributing to environmental sustainability and reducing waste.

Recycled Plastic Raw Materials:

We have both Post Industrial and Post Consumer waste material as follows.

HDPE Film Material

HDPE Film/Injection & Blow Material refers to High-Density Polyethylene used in the form of solid or regrind. It is a versatile plastic material known for its high density, strength, and chemical resistance. It can be processed through injection molding or blow molding techniques to produce a wide range of products. HDPE film/injection & blow material offers durability, moisture resistance, UV resistance, and recyclability. It is widely used in industries such as packaging, manufacturing, construction, and agriculture.

- Easy loading

- Targeted dispensing

- Enhanced portability

- Controlled release

- Protection and sealing

- Source: Water bottle (5 gallons)

- Colors: Transparent light blue

- Packing (Shipping bags): Jumbo bags

LDPE, PP & HDPE Lumps

HDPE Lumps: HDPE is a durable and versatile plastic widely used in packaging, pipes, and construction materials. HDPE lumps are solid chunks or irregular pieces of high-density polyethylene plastic. HDPE is known for its high strength, impact resistance, and excellent chemical resistance.

- Easy handling and transportation.

- Controlled dispensing or release.

- Space-efficient storage.

- Targeted and precise application.

- Protection and sealing of contents.

LDPE, PP & HDPE Lumps

HDPE Lumps: HDPE is a durable and versatile plastic widely used in packaging, pipes, and construction materials. HDPE lumps are solid chunks or irregular pieces of high-density polyethylene plastic. HDPE is known for its high strength, impact resistance, and excellent chemical resistance.

- Easy handling and transportation.

- Controlled dispensing or release.

- Space-efficient storage.

- Targeted and precise application.

- Protection and sealing of contents.